Product Description:

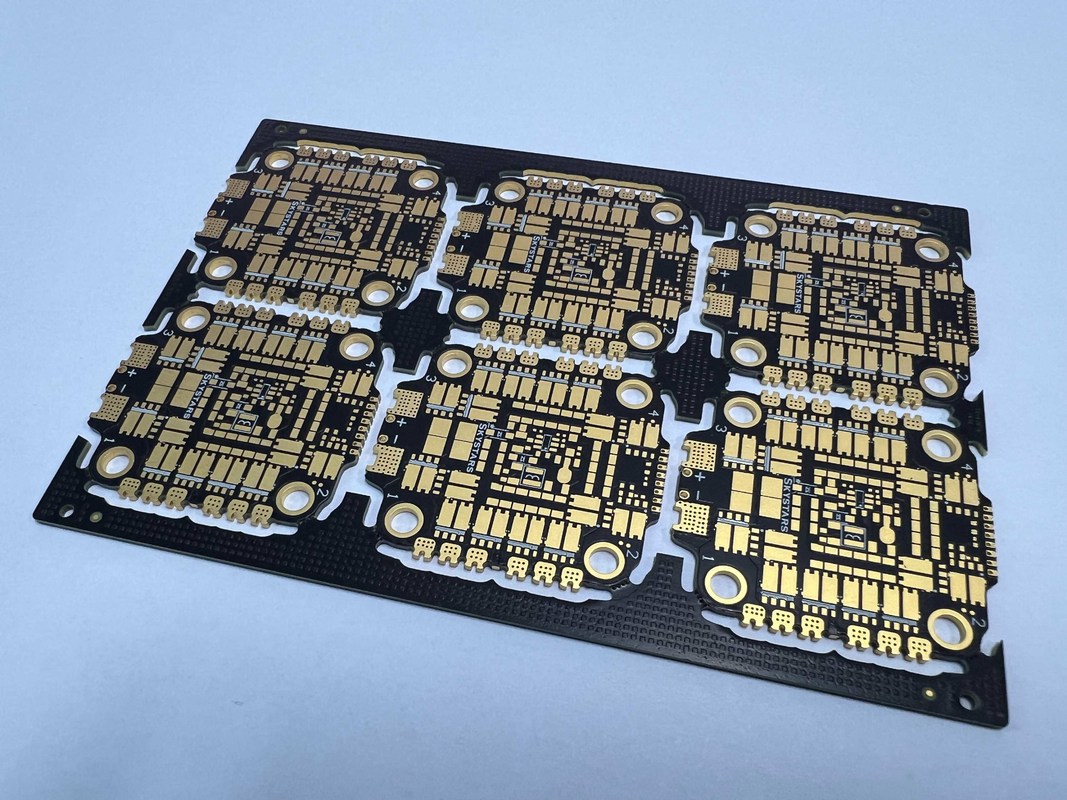

The HDI PCB Board is a cutting-edge product that offers exceptional performance and reliability for a wide range of applications. With its advanced features and high-quality construction, it is an ideal choice for demanding electronic projects.

Featuring the innovative Vip Process, this HDI PCB Board is designed to meet the requirements of modern electronic devices. The Vip Process ensures superior connectivity and signal transmission, making it suitable for high-speed applications.

One of the key attributes of the HDI PCB Board is its High Density Interconnector (HDI) technology. This technology allows for a higher wiring density and more compact design, making it ideal for applications where space is limited.

With a Copper Thickness ranging from 0.5oz to 6oz, the HDI PCB Board offers excellent conductivity and thermal performance. This ensures reliable and efficient operation, even under demanding conditions.

The Vias Aspect Ratio of 16:1 further enhances the performance of the HDI PCB Board. This aspect ratio provides optimal signal integrity and reliability, making it suitable for high-frequency applications.

When it comes to design options, the HDI PCB Board offers a variety of choices. The Silkscreen can be customized in White, Black, Yellow, and other colors, allowing for easy identification and branding of the board.

Whether you are working on a complex electronic project or developing a high-definition video converter like the HD SDI Converter, the HDI PCB Board is a reliable and versatile solution. Its advanced features and high-quality construction make it a top choice for electronics engineers and designers.

Overall, the HDI PCB Board is a premium product that combines cutting-edge technology with exceptional performance. With its Vip Process, High Density Interconnector technology, and customizable design options, it is the ideal choice for demanding electronic applications.

Features:

-

Product Name: HDI PCB Board

-

Surface Finish: HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Etc.

-

Vip Process: Yes

-

Vias Aspect Ratio: 16:1

-

Glass Epoxy: RO4350B Tg280℃, Er<3.48, Rogers Corp.

-

Min. Solder Mask Bridge: 0.075mm

Technical Parameters:

|

Key Words

|

High Density Interconnector

|

|

Glass Epoxy

|

RO4350B Tg280℃, Er<3.48, Rogers Corp.

|

|

Copper Thickness

|

0.5oz-6oz

|

|

Vip Process

|

Yes

|

|

Thickness

|

1.6mm, ±10%

|

|

Silkscreen

|

White, Black, Yellow, Etc.

|

|

Finished Copper Thickness

|

1oz

|

|

Surface Finish

|

HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Etc.

|

|

Aspect Ratio

|

10:1

|

|

Surface Mount Technology

|

Available

|

Applications:

HDI PCB boards are widely used in various high-tech industries and applications due to their advanced features and capabilities. The key attributes of HDI PCB boards, such as high copper thickness ranging from 0.5oz to 6oz, a thickness of 1.6mm with a tolerance of ±10%, and the use of high-quality Glass Epoxy material like RO4350B Tg280℃ with Er<3.48 from Rogers Corp, make them ideal for demanding and high-performance scenarios.

One of the primary application occasions for HDI PCB boards is in the field of telecommunications. These boards are perfect for high-speed data transmission, making them essential for networking equipment, routers, and communication devices. Their high density interconnector design allows for efficient signal routing and reduced signal loss, ensuring reliable and stable communication.

Another key scenario for HDI PCB boards is in the aerospace industry, where reliability and precision are paramount. The high copper thickness and finished copper thickness of 1oz provide excellent conductivity and thermal management, making them suitable for use in aircraft systems, satellites, and space exploration technologies.

Furthermore, HDI PCB boards find extensive applications in the medical field, particularly in advanced medical devices and equipment. The high density interconnector design allows for compact and lightweight PCBs, making them ideal for portable medical devices, diagnostic tools, and monitoring systems.

In the automotive industry, HDI PCB boards play a crucial role in modern vehicles' electronic systems. Their high-speed PCB board capabilities enable efficient data processing for automotive control units, infotainment systems, and driver-assistance technologies, enhancing overall vehicle performance and safety.

In summary, the versatile nature of HDI PCB boards, combined with their high-density interconnector design and advanced specifications, make them suitable for a wide range of application occasions and scenarios in industries such as telecommunications, aerospace, medical, automotive, and many others requiring high-speed and high-performance PCB solutions.

Customization:

Product Customization Services for HDI PCB Board:

Key Words: HDI PCB, HDI PCB Manufacturing, High Speed PCB Board

Surface Mount Technology: Available

Aspect Ratio: 10:1

VIP Process: Yes

Glass Epoxy: RO4350B Tg280℃, Er<3.48, Rogers Corp.

Support and Services:

The HDI PCB Board product comes with comprehensive Product Technical Support and Services to assist customers in utilizing the product effectively. Our dedicated technical support team is available to address any product-related queries and provide guidance on installation, troubleshooting, and maintenance.

Additionally, customers can benefit from our range of services, including product training, warranty support, and repair services. We are committed to delivering high-quality technical support and services to ensure customer satisfaction and product performance.

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!  আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!